Samples of each packaging shall be prepared as for carriage, except that a liquid or solid infectious

substance shall be replaced by water or, where conditioning at –18 °C is specified, by

water/antifreeze. Each primary receptacle shall be filled to not less than 98% of its capacity.

NOTE: The term water includes water/antifreeze solution with a minimum specific gravity of 0.95

for testing at – 18 °C.

Tests and number of samples required

Tests required for packaging types

|

Type of packaging a

|

Tests required

|

|

Rigid outer packaging

|

Primary receptacle

|

Water spray 6.3.5.3.6.1

|

Cold conditioning 6.3.5.3.6.2

|

Drop 6.3.5.3

|

Additional drop 6.3.5.3.6.3

|

Puncture 6.3.5.4

|

Stack 6.1.5.6

|

|

Plastics

|

Other

|

|

No. of samples

|

No. of samples

|

No. of samples

|

No. of samples

|

No. of samples

|

No. of samples

|

|

Fibreboard box

|

x

|

|

5

|

5

|

10

|

|

|

|

|

|

x

|

5

|

0

|

5

|

2

|

|

Fibreboard drum

|

x

|

|

3

|

3

|

6

|

2

|

|

|

Required on three samples when testing a "U"-marked packaging as defined in

6.3.5.1.6 for specific provisions.

|

|

|

x

|

3

|

0

|

3

|

2

|

|

Plastics box

|

x

|

|

0

|

5

|

5

|

2

|

|

|

x

|

0

|

5

|

5

|

2

|

|

Plastics drum/ jerrican

|

x

|

|

0

|

3

|

3

|

2

|

|

|

x

|

0

|

3

|

3

|

2

|

|

Boxes of other material

|

x

|

|

0

|

5

|

5

|

2

|

|

|

x

|

0

|

0

|

5

|

2

|

|

Drums/ jerricans of other material

|

x

|

|

0

|

3

|

3

|

2

|

|

|

x

|

0

|

0

|

3

|

2

|

a "Type of packaging" categorizes packagings for test purposes according to the kind of packaging and its

material characteristics.

NOTE 1: In instances where a primary receptacle is made of two or more materials, the

material most liable to damage determines the appropriate test.

NOTE 2: The material of the secondary packagings are not taken into consideration when

selecting the test or conditioning for the test.

Explanation for use of the table:

If the packaging to be tested consists of a fibreboard outer box with a plastics primary receptacle, five

samples must undergo the water spray test (see 6.3.5.3.6.1) prior to dropping and another five must be

conditioned to – 18 °C (see 6.3.5.3.6.2) prior to dropping. If the packaging is to contain dry ice then

one further single sample shall be dropped five times after conditioning in accordance with

6.3.5.3.6.3.

Packagings prepared as for carriage shall be subjected to the tests in 6.3.5.3 and 6.3.5.4. For outer

packagings, the headings in the table relate to fibreboard or similar materials whose performance may

be rapidly affected by moisture; plastics which may embrittle at low temperature; and other materials

such as metal whose performance is not affected by moisture or temperature.

Drop test

Samples shall be subjected to free-fall drops from a height of 9 m onto a non-resilient, horizontal, flat,

massive and rigid surface in conformity with 6.1.5.3.4.

Where the samples are in the shape of a box, five shall be dropped one in each of the following

orientations:

(a) flat on the base;

(b) flat on the top;

(c) flat on the longest side;

(d) flat on the shortest side;

(e) on a corner.

Where the samples are in the shape of a drum, three shall be dropped one in each of the following

orientations:

(a) diagonally on the top chime, with the centre of gravity directly above the point of

impact;

(b) diagonally on the base chime;

(c) flat on the side.

While the sample shall be released in the required orientation, it is accepted that for aerodynamic

reasons the impact may not take place in that orientation.

Following the appropriate drop sequence, there shall be no leakage from the primary receptacle(s)

which shall remain protected by cushioning/absorbent material in the secondary packaging.

Special preparation of test sample for the drop test

Fibreboard - Water spray test

Fibreboard outer packagings: The sample shall be subjected to a water spray that simulates exposure

to rainfall of approximately 5 cm per hour for at least one hour. It shall then be subjected to the test

described in 6.3.5.3.1.

Plastics material – Cold conditioning

Plastics primary receptacles or outer packagings: The temperature of the test sample and its contents

shall be reduced to – 18 °C or lower for a period of at least 24 hours and within 15 minutes of removal

from that atmosphere the test sample shall be subjected to the test described in 6.3.5.3.1. Where the

sample contains dry ice, the conditioning period shall be reduced to 4 hours.

Packagings intended to contain dry ice – Additional drop test

Where the packaging is intended to contain dry ice, a test additional to that specified in 6.3.5.3.1 and,

when appropriate, in 6.3.5.3.6.1 or 6.3.5.3.6.2 shall be carried out. One sample shall be stored so that

all the dry ice dissipates and then that sample shall be dropped in one of the orientations described in

6.3.5.3.2 which shall be that most likely to result in failure of the packaging.

Puncture test

Packagings with a gross mass of 7 kg or less

Samples shall be placed on a level hard surface. A cylindrical steel rod with a mass of at least 7 kg, a

diameter of 38 mm and whose impact end edges have a radius not exceeding 6 mm (see Figure

6.3.5.4.2), shall be dropped in a vertical free fall from a height of 1 m, measured from the impact end

to the impact surface of the sample. One sample shall be placed on its base. A second sample shall be

placed in an orientation perpendicular to that used for the first. In each instance the steel rod shall be

aimed to impact the primary receptacle. Following each impact, penetration of the secondary

packaging is acceptable, provided that there is no leakage from the primary receptacle(s).

Packagings with a gross mass exceeding 7 kg

Samples shall be dropped on to the end of a cylindrical steel rod. The rod shall be set vertically in a

level hard surface. It shall have a diameter of 38 mm and the edges of the upper end a radius not

exceeding 6 mm (see Figure 6.3.5.4.2). The rod shall protrude from the surface a distance at least

equal to that between the centre of the primary receptacle(s) and the outer surface of the outer

packaging with a minimum of 200 mm. One sample shall be dropped with its top face lowermost in a

vertical free fall from a height of 1 m, measured from the top of the steel rod. A second sample shall

be dropped from the same height in an orientation perpendicular to that used for the first. In each

instance, the packaging shall be so orientated that the steel rod would be capable of penetrating the

primary receptacle(s). Following each impact, penetration of the secondary packaging is acceptable

provided that there is no leakage from the primary receptacle(s).

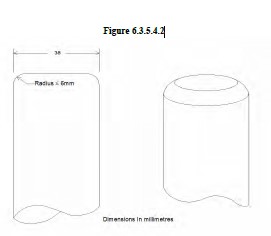

Figure 6.3.5.4.2