Packagings with a gross mass of 7 kg or less

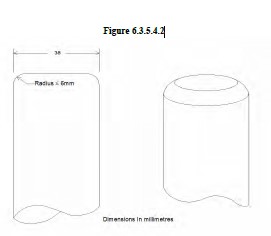

Samples shall be placed on a level hard surface. A cylindrical steel rod with a mass of at least 7 kg, a

diameter of 38 mm and whose impact end edges have a radius not exceeding 6 mm (see Figure

6.3.5.4.2), shall be dropped in a vertical free fall from a height of 1 m, measured from the impact end

to the impact surface of the sample. One sample shall be placed on its base. A second sample shall be

placed in an orientation perpendicular to that used for the first. In each instance the steel rod shall be

aimed to impact the primary receptacle. Following each impact, penetration of the secondary

packaging is acceptable, provided that there is no leakage from the primary receptacle(s).

Packagings with a gross mass exceeding 7 kg

Samples shall be dropped on to the end of a cylindrical steel rod. The rod shall be set vertically in a

level hard surface. It shall have a diameter of 38 mm and the edges of the upper end a radius not

exceeding 6 mm (see Figure 6.3.5.4.2). The rod shall protrude from the surface a distance at least

equal to that between the centre of the primary receptacle(s) and the outer surface of the outer

packaging with a minimum of 200 mm. One sample shall be dropped with its top face lowermost in a

vertical free fall from a height of 1 m, measured from the top of the steel rod. A second sample shall

be dropped from the same height in an orientation perpendicular to that used for the first. In each

instance, the packaging shall be so orientated that the steel rod would be capable of penetrating the

primary receptacle(s). Following each impact, penetration of the secondary packaging is acceptable

provided that there is no leakage from the primary receptacle(s).

Figure 6.3.5.4.2

Test report

A written test report containing at least the following particulars shall be drawn up and shall be

available to the users of the packaging:

1. Name and address of the test facility;

2. Name and address of applicant (where appropriate);

3. A unique test report identification;

4. Date of the test and of the report;

5. Manufacturer of the packaging;

6. Description of the packaging design type (e.g. dimensions, materials, closures, thickness, etc.),

including method of manufacture (e.g. blow moulding) and which may include drawing(s)

and/or photograph(s);

7. Maximum capacity;

8. Test contents;

9. Test descriptions and results;

10. The test report shall be signed with the name and status of the signatory.

The test report shall contain statements that the packaging prepared as for carriage was tested in

accordance with the appropriate requirements of this Chapter and that the use of other packaging

methods or components may render it invalid. A copy of the test report shall be available to the

competent authority.

REQUIREMENTS FOR THE CONSTRUCTION, TESTING AND APPROVAL OF PACKAGES FOR RADIOACTIVE MATERIAL AND FOR THE APPROVAL OF SUCH MATERIAL

(Reserved)

General requirements

The package shall be so designed in relation to its mass, volume and shape that it can be easily and

safely carried. In addition, the package shall be so designed that it can be properly secured in or on the

vehicle during carriage.

The design shall be such that any lifting attachments on the package will not fail when used in the

intended manner and that, if failure of the attachments should occur, the ability of the package to meet

other requirements of this Annex would not be impaired. The design shall take account of appropriate

safety factors to cover snatch lifting.

Attachments and any other features on the outer surface of the package which could be used to lift it

shall be designed either to support its mass in accordance with the requirements of 6.4.2.2 or shall be

removable or otherwise rendered incapable of being used during carriage.

As far as practicable, the packaging shall be so designed and finished that the external surfaces are

free from protruding features and can be easily decontaminated.

As far as practicable, the outer layer of the package shall be so designed as to prevent the collection

and the retention of water.

Any features added to the package at the time of carriage which are not part of the package shall not

reduce its safety.

The package shall be capable of withstanding the effects of any acceleration, vibration or vibration

resonance which may arise under routine conditions of carriage without any deterioration in the

effectiveness of the closing devices on the various receptacles or in the integrity of the package as a

whole. In particular, nuts, bolts and other securing devices shall be so designed as to prevent them

from becoming loose or being released unintentionally, even after repeated use.