(Reserved)

(Reserved)

Designatory code system for IBCs

|

Type |

|||

|

under press than 10 kPa (0.1 bar) |

r liquids |

||

|

Rigid |

11 |

21 |

31 |

|

Flexible |

13 |

- |

- |

The following types and codes of IBC are assigned:

|

Material |

Category |

Code |

Sub- section |

|

Metal |

|||

|

11A |

|||

|

for solids, filled or discharged under pressure |

21A |

||

|

for liquids |

31A |

||

|

B. Aluminium |

for solids, filled or discharged by gravity |

11B |

|

|

for solids, filled or discharged under pressure |

21B |

6.5.5.1 |

|

|

for liquids |

31B |

||

|

N. Other than steel or aluminium |

for solids, filled or discharged by gravity |

11N |

|

|

for solids, filled or discharged under pressure |

21N |

||

|

for liquids |

31N |

||

|

Flexible |

|||

|

H. Plastics |

woven plastics without coating or liner |

13H1 |

|

|

woven plastics, coated |

13H2 |

||

|

woven plastics with liner |

13H3 |

||

|

woven plastics, coated and with liner |

13H4 |

||

|

plastics film |

13H5 |

||

|

L. Textile |

without coating or liner |

13L1 |

6.5.5.2 |

|

coated |

13L2 |

||

|

with liner |

13L3 |

||

|

coated and with liner |

13L4 |

||

|

M. Paper |

multiwall |

13M1 |

|

|

multiwall, water resistant |

13M2 |

||

|

H. Rigid plastics |

for solids, filled or discharged by gravity, fitted with |

11H1 |

|

|

s, filled or discharged by gravity, freestanding |

11H2 |

||

|

for solids, filled or discharged under pressure, fitted with structural equipment |

21H1 |

6.5.5.3 |

|

|

for solids, filled or discharged under pressure, freestanding |

21H2 |

||

|

for liquids, fitted with structural equipment |

31H1 |

||

|

for liquids, freestanding |

31H2 |

|

Material |

Category |

Code |

Sub- section |

|

HZ. Composite tics inner |

for solids, filled or discharged by gravity, with rigid plastics inner receptacle |

11HZ1 |

6.5.5.4 |

|

with flexible |

11HZ2 |

||

|

for solids, filled or discharged under pressure, with rigid plastics inner receptacle |

21HZ1 |

||

|

for solids, filled or discharged under pressure, with flexible plastics inner receptacle |

21HZ2 |

||

|

for liquids, with rigid plastics inner receptacle |

31HZ1 |

||

|

for liquids, with flexible plastics inner receptacle |

31HZ2 |

||

|

G. Fibreboard |

for solids, filled or discharged by gravity |

11G |

6.5.5.5 |

|

Wooden |

|||

|

C. Natural wood |

for solids, filled or discharged by gravity with inner liner |

11C |

6.5.5.6 |

|

D. Plywood |

for solids, filled or discharged by gravity, with inner liner |

11D |

|

|

F. Reconstituted wood |

for solids, filled or discharged by gravity, with inner liner |

11F |

|

Marking

Primary marking

;

;

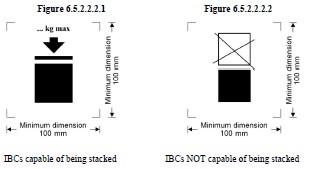

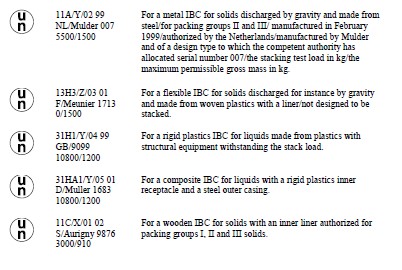

Examples of marking for various types of IBC in accordance with 6.5.2.1.1 (a) to (h) above:

Additional marking

Each IBC shall bear the marks required in 6.5.2.1 and, in addition, the following information which

may appear on a corrosion-resistant plate permanently attached in a place readily accessible for inspection:

|

Additional marks |

Category of IBC |

||||

|

Metal |

Rigid plastics |

Composite |

Fibreboard |

Wooden |

|

|

Capacity in litres a at 20 °C |

X |

X |

X |

||

|

Tare mass in kg a |

X |

X |

X |

X |

X |

|

Test (gauge) pressure, in kPa or bar a, if applicable |

X |

X |

|||

|

Maximum filling / discharge pressure in kPa or bar a , if applicable |

X |

X |

X |

||

|

Body material and its minimum thickness in mm |

X |

||||

|

Date of last leakproofness test, if applicable (month and year) |

X |

X |

X |

||

|

Date of last inspection (month and year) |

X |

X |

X |

||

|

Serial number of the manufacturer |

X |

||||

|

Maximum permitted stacking load b |

X |

X |

X |

X |

X |

a The unit used shall be indicated.

b See 6.5.2.2.2. This additional mark shall apply to all IBCs manufactured, repaired or remanufactured as from 1 January 2011 (see also 1.6.1.15).