Manufacturers and subsequent distributors of packagings shall provide information regarding

procedures to be followed and a description of the types and dimensions of closures (including

required gaskets) and any other components needed to ensure that packages as presented for carriage

are capable of passing the applicable performance tests of this Chapter.

Code for designating types of large packagings

The code used for large packagings consist of:

(a) Two Arabic numerals:

50 for rigid large packagings; or

51 for flexible large packagings; and

(b) A capital letter in Latin character indicating the nature of the material, e.g. wood, steel etc. The

capital letters used shall be those shown in 6.1.2.6.

The letters "T" or "W" may follow the Large Packaging code. The letter "T" signifies a large salvage

packaging conforming to the requirements of 6.6.5.1.9. The letter "W" signifies that the large

packaging, although of the same type indicated by the code, is manufactured to a specification

different from those in 6.6.4 and is considered equivalent in accordance with the requirements

in 6.6.1.3.

Marking

Primary marking

Each large packaging manufactured and intended for use in accordance with the provisions of ADR

shall bear marks which are durable, legible and placed in a location so as to be readily visible.

Letters, numerals and symbols shall be at least 12 mm high and shall show:

(a) The United Nations packaging symbol  ;

;

;

;

This symbol shall not be used for any purpose other than certifying that a packaging, a flexible

bulk container, a portable tank or a MEGC complies with the relevant requirements in Chapter

6.1, 6.2, 6.3, 6.5, 6.6, 6.7 or 6.11. For metal large packagings on which the marks are stamped or

embossed, the capital letters "UN" may be applied instead of the symbol;

(b) The number "50" designating a large rigid packaging or "51" for flexible large packagings,

followed by the material type in accordance with 6.5.1.4.1 (b);

(c) A capital letter designating the packing group(s) for which the design type has been

approved:

X for packing groups I, II and III Y for packing groups II and III Z for packing group III only;

(d) The month and year (last two digits) of manufacture;

(e) The State authorizing the allocation of the mark; indicated by the distinguishing sign used on

vehicles in international road traffic1;

(f) The name or symbol of the manufacturer and other identification of the large packagings as

specified by the competent authority;

(g) The stacking test load in kg. For large packagings not designed for stacking the figure "0"

shall be shown;

(h) The maximum permissible gross mass in kilograms.

The primary mark required above shall be applied in the sequence of the sub-paragraphs.

Each mark applied in accordance with (a) to (h) shall be clearly separated, e.g. by a slash or

space, so as to be easily identifiable.

1 Distinguishing sign of the State of registration used on motor vehicles and

trailers in international road traffic, in accordance with the Geneva Convention on Road Traffic of

1949 or the Vienna Convention on Road Traffic of

1968.

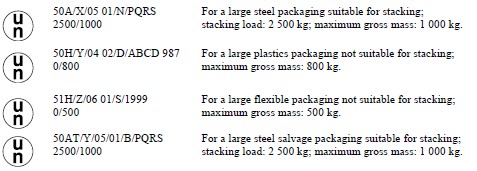

Examples of marking

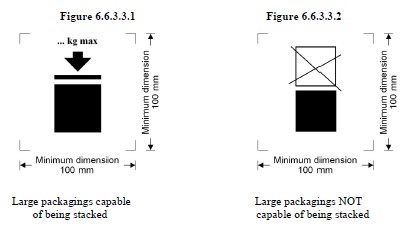

The maximum permitted stacking load applicable when the large packaging is in use shall be

displayed on a symbol as shown in Figure 6.6.3.3.1 or Figure 6.6.3.3.2. The symbol shall be durable

and clearly visible.

The minimum dimensions shall be 100 mm x 100 mm. The letters and numbers indicating the mass

shall be at least 12 mm high. The area within the printer’s marks indicated by the dimensional arrows

shall be square. Where dimensions are not specified, all features shall be in approximate proportion to

those shown. The mass marked above the symbol shall not exceed the load imposed during the design

type test (see 6.6.5.3.3.4) divided by 1.8.

Specific requirements for large packagings

Specific requirements for metal large packagings

50A steel

50B aluminium

50N metal (other than steel or aluminium)

The large packaging shall be made of suitable ductile metal in which the weldability has been fully

demonstrated. Welds shall be skilfully made and afford complete safety. Low-temperature

performance shall be taken into account when appropriate.

Care shall be taken to avoid damage by galvanic action due to the juxtaposition of dissimilar metals.

Specific requirements for flexible material large packagings

51H flexible plastics

51M flexible paper

The large packaging shall be manufactured from suitable materials. The strength of the material and

the construction of the flexible large packagings shall be appropriate to its capacity and its intended

use.

All materials used in the construction of flexible large packagings of types 51M shall, after complete

immersion in water for not less than 24 hours, retain at least 85% of the tensile strength as measured

originally on the material conditioned to equilibrium at 67% relative humidity or less.