2.5 year periodic inspection and test as required by 6.7.2.19.2. However, a portable tank filled prior to

the date of expiry of the last periodic inspection and test may be carried for a period not to exceed

three months beyond the date of expiry of the last periodic test or inspection. In addition, a portable

tank may be carried after the date of expiry of the last periodic test and inspection:

(a) After emptying but before cleaning, for purposes of performing the next required test or

inspection prior to refilling; and

(b) Unless otherwise approved by the competent authority, for a period not to exceed six months

beyond the date of expiry of the last periodic test or inspection, in order to allow the return of

dangerous goods for proper disposal or recycling. Reference to this exemption shall be

mentioned in the transport document.

The exceptional inspection and test is necessary when the portable tank shows evidence of damaged

or corroded areas, or leakage, or other conditions that indicate a deficiency that could affect the

integrity of the portable tank. The extent of the exceptional inspection and test shall depend on the

amount of damage or deterioration of the portable tank. It shall include at least the 2.5 year inspection

and test according to 6.7.2.19.5.

The internal and external examinations shall ensure that:

(a) The shell is inspected for pitting, corrosion, or abrasions, dents, distortions, defects in welds or

any other conditions, including leakage, that might render the portable tank unsafe for carriage.

The wall thickness shall be verified by appropriate measurement if this inspection indicates a

reduction of wall thickness;

(b) The piping, valves, heating/cooling system, and gaskets are inspected for corroded areas,

defects, or any other conditions, including leakage, that might render the portable tank unsafe

for filling, discharge or carriage;

(c) Devices for tightening manhole covers are operative and there is no leakage at manhole covers

or gaskets;

(d) Missing or loose bolts or nuts on any flanged connection or blank flange are replaced or

tightened;

(e) All emergency devices and valves are free from corrosion, distortion and any damage or defect

that could prevent their normal operation. Remote closure devices and self-closing stop-valves

shall be operated to demonstrate proper operation;

(f) Linings, if any, are inspected in accordance with criteria outlined by the lining manufacturer;

(g) Required marks on the portable tank are legible and in accordance with the applicable

requirements; and

(h) The framework, supports and arrangements for lifting the portable tank are in a satisfactory

condition.

The inspections and tests in 6.7.2.19.1, 6.7.2.19.3, 6.7.2.19.4, 6.7.2.19.5 and 6.7.2.19.7 shall be

performed or witnessed by an expert approved by the competent authority or its authorized body.

When the pressure test is a part of the inspection and test, the test pressure shall be the one indicated

on the data plate of the portable tank. While under pressure, the portable tank shall be inspected for

any leaks in the shell, piping or equipment.

In all cases when cutting, burning or welding operations on the shell have been effected, that work

shall be to the approval of the competent authority or its authorized body taking into account the

pressure vessel code used for the construction of the shell. A pressure test to the original test pressure

shall be performed after the work is completed.

When evidence of any unsafe condition is discovered, the portable tank shall not be returned to

service until it has been corrected and the test is repeated and passed. .

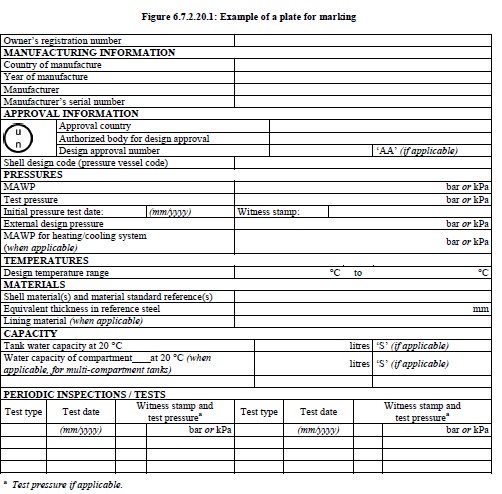

Marking

Every portable tank shall be fitted with a corrosion resistant metal plate permanently attached to the

portable tank in a conspicuous place readily accessible for inspection. When for reasons of portable

tank arrangements the plate cannot be permanently attached to the shell, the shell shall be marked with

at least the information required by the pressure vessel code. As a minimum, at least the following

information shall be marked on the plate by stamping or by any other similar method:

(a) Owner information

(i) Owner’s registration number;

(b) Manufacturing information

(i) Country of manufacture;

(ii) Year of manufacture;

(iii) Manufacturer’s name or mark;

(iv) Manufacturer’s serial number;

(c) Approval information

(i) The United Nations packaging symbol

;

This symbol shall not be used for any purpose other than certifying that a packaging, a

flexible bulk container, a portable tank or a MEGC complies with the relevant

requirements in Chapter 6.1, 6.2, 6.3, 6.5, 6.6, 6.7 or 6.11;

(ii) Approval country;

(iii) Authorized body for the design approval;

(iv) Design approval number;

(v) Letters ‘AA’, if the design was approved under alternative arrangements (see 6.7.1.2);

(vi) Pressure vessel code to which the shell is designed;

(d) Pressures

(i) MAWP (in bar gauge or kPa gauge)3;

(ii) Test pressure (in bar gauge or kPa gauge)3;

(iii) Initial pressure test date (month and year);

(iv) Identification mark of the initial pressure test witness;

(v) External design pressure4 (in bar gauge or kPa gauge)3;

(vi) MAWP for heating/cooling system (in bar gauge or kPa gauge)3 (when applicable);

(e) Temperatures

(i) Design temperature range (in °C)3;

3 The unit used shall be indicated.

4 See 6.7.2.2.10.

(f) Materials

(i) Shell material(s) and material standard reference(s);

(ii) Equivalent thickness in reference steel (in mm)3;

(iii) Lining material (when applicable);

(g) Capacity

(i) Tank water capacity at 20 °C (in litres)3;

This indication is to be followed by the symbol "S" when the shell is divided by surge

plates into sections of not more than 7 500 litres capacity;

(ii) Water capacity of each compartment at 20 °C (in litres)3 (when applicable, for multicompartment

tanks).

This indication is to be followed by the symbol "S" when the compartment is divided by

surge plates into sections of not more than 7 500 litres capacity;

(h) Periodic inspections and tests

(i) Type of the most recent periodic test (2.5-year, 5-year or exceptional);

(ii) Date of the most recent periodic test (month and year);

(iii) Test pressure (in bar gauge or kPa gauge)3 of the most recent periodic test (if

applicable);

(iv) Identification mark of the authorized body who performed or witnessed the most recent

test.

3 The unit used shall be indicated.

The following particulars shall be durably marked either on the portable tank itself or on a metal plate

firmly secured to the portable tank:

Name of the operator

Maximum permissible gross mass (MPGM) ___________ kg

Unladen (tare) mass ___________ kg

Portable tank instruction in accordance with 4.2.5.2.6

NOTE: For the identification of the substances being carried, see also Part 5.

If a portable tank is designed and approved for handling in open seas, the words "OFFSHORE

PORTABLE TANK" shall be marked on the identification plate.

Requirements for the design, construction, inspection and testing of portable tanks intended for the carriage of non-refrigerated liquefied gases

NOTE: These requirements also apply to portable tanks intended for the carriage of chemicals under

pressure (UN Nos. 3500, 3501, 3502, 3503, 3504 and 3505).

Definitions

For the purposes of this section:

Alternative arrangement means an approval granted by the competent authority for a portable tank or

MEGC that has been designed, constructed or tested to technical requirements or testing methods

other than those specified in this Chapter;

Portable tank means a multimodal tank having a capacity of more than 450 litres used for the carriage

of non-refrigerated liquefied gases of Class 2. The portable tank includes a shell fitted with service

equipment and structural equipment necessary for the carriage of gases. The portable tank shall be

capable of being filled and discharged without the removal of its structural equipment. It shall possess

stabilizing members external to the shell, and shall be capable of being lifted when full. It shall be

designed primarily to be loaded onto a vehicle, wagon or sea-going or inland navigation vessel and

shall be equipped with skids, mountings or accessories to facilitate mechanical handling. Tankvehicles,

tank-wagons, non-metallic tanks, intermediate bulk containers (IBCs), gas cylinders and

large receptacles are not considered to fall within the definition for portable tanks;

Shell means the part of the portable tank which retains the non-refrigerated liquefied gas intended for

carriage (tank proper), including openings and their closures, but does not include service equipment

or external structural equipment;

Service equipment means measuring instruments and filling, discharge, venting, safety and insulating

devices;

Structural equipment means the reinforcing, fastening, protective and stabilizing members external to

the shell;

Maximum allowable working pressure (MAWP) means a pressure that shall be not less than the

highest of the following pressures measured at the top of the shell while in operating position, but in

no case less than 7 bar:

(a) The maximum effective gauge pressure allowed in the shell during filling or discharge; or

(b) The maximum effective gauge pressure to which the shell is designed, which shall be:

(i) for a non-refrigerated liquefied gas listed in the portable tank instruction T50

in 4.2.5.2.6, the MAWP (in bar) given in T50 portable tank instruction for that gas;

(ii) for other non-refrigerated liquefied gases, not less than the sum of:

- the absolute vapour pressure (in bar) of the non-refrigerated liquefied gas at the

design reference temperature minus 1 bar; and

- the partial pressure (in bar) of air or other gases in the ullage space

being determined by the design reference temperature and the liquid phase

expansion due to an increase of the mean bulk temperature of tr -tf (tf = filling

temperature, usually 15 °C, tr = maximum mean bulk temperature, 50 °C);

(iii) for chemicals under pressure, the MAWP (in bar) given in T50 portable tank instruction

for the liquefied gas portion of the propellants listed in T50 in 4.2.5.2.6;

Design pressure means the pressure to be used in calculations required by a recognized pressure

vessel code. The design pressure shall be not less than the highest of the following pressures:

(a) The maximum effective gauge pressure allowed in the shell during filling or discharge; or

(b) The sum of:

(i) the maximum effective gauge pressure to which the shell is designed as defined in (b) of

the MAWP definition (see above); and

(ii) a head pressure determined on the basis of the static forces specified in 6.7.3.2.9, but not

less than 0.35 bar;

Test pressure means the maximum gauge pressure at the top of the shell during the pressure test;

Leakproofness test means a test using gas subjecting the shell and its service equipment to an effective

internal pressure of not less than 25% of the MAWP;

Maximum permissible gross mass (MPGM) means the sum of the tare mass of the portable tank and

the heaviest load authorized for carriage;

Reference steel means a steel with a tensile strength of 370 N/mm2 and an elongation at fracture

of 27%;

Mild steel means a steel with a guaranteed minimum tensile strength of 360 N/mm2 to 440 N/mm2 and

a guaranteed minimum elongation at fracture conforming to 6.7.3.3.3.3;

Design temperature range for the shell shall be -40 °C to 50 °C for non-refrigerated liquefied gases

carried under ambient conditions. More severe design temperatures shall be considered for portable

tanks subjected to severe climatic conditions;

Design reference temperature means the temperature at which the vapour pressure of the contents is

determined for the purpose of calculating the MAWP. The design reference temperature shall be less

than the critical temperature of the non-refrigerated liquefied gas or liquefied gas propellants of

chemicals under pressure intended to be carried to ensure that the gas at all times is liquefied. This

value for each portable tank type is as follows:

(a) Shell with a diameter of 1.5 metres or less: 65 °C;

(b) Shell with a diameter of more than 1.5 metres:

(i) without insulation or sun shield: 60 °C;

(ii) with sun shield (see 6.7.3.2.12): 55 °C; and

(iii) with insulation (see 6.7.3.2.12) : 50 °C;

Filling density means the average mass of non-refrigerated liquefied gas per litre of shell capacity

(kg/l). The filling density is given in portable tank instruction T50 in 4.2.5.2.6.

General design and construction requirements

Shells shall be designed and constructed in accordance with the requirements of a pressure vessel code

recognized by the competent authority. Shells shall be made of steel suitable for forming. The

materials shall in principle conform to national or international material standards. For welded shells,

only a material whose weldability has been fully demonstrated shall be used. Welds shall be skilfully

made and afford complete safety. When the manufacturing process or the materials make it necessary,

the shells shall be suitability heat-treated to guarantee adequate toughness in the weld and in the heat

affected zones. In choosing the material the design temperature range shall be taken into account with

respect to risk of brittle fracture, to stress corrosion cracking and to resistance to impact. When fine

grain steel is used, the guaranteed value of the yield strength shall be not more than 460 N/mm2 and

the guaranteed value of the upper limit of the tensile strength shall be not more than 725 N/mm2

according to the material specification. Portable tank materials shall be suitable for the external

environment in which they may be carried.

Portable tank shells, fittings and pipework shall be constructed of materials which are:

(a) Substantially immune to attack by the non-refrigerated liquefied gas(es) intended to be

carried; or

(b) Properly passivated or neutralized by chemical reaction.