In all cases when cutting, burning or welding operations on the shell have been effected, that work

shall be to the approval of the competent authority or its authorized body taking into account the

pressure vessel code used for the construction of the shell. A pressure test to the original test pressure

shall be performed after the work is completed.

When evidence of any unsafe condition is discovered, the portable tank shall not be returned to

service until it has been corrected and the pressure test is repeated and passed.

Marking

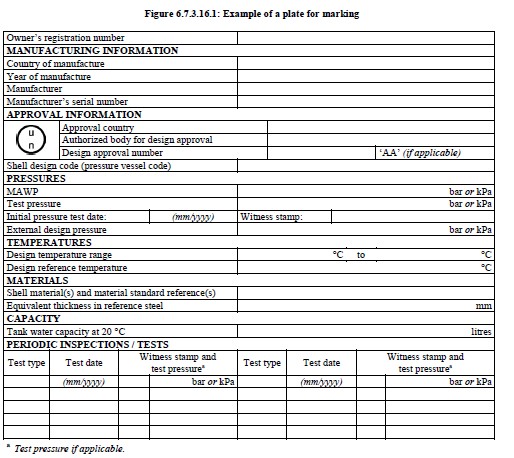

Every portable tank shall be fitted with a corrosion resistant metal plate permanently attached to the

portable tank in a conspicuous place readily accessible for inspection. When for reasons of portable

tank arrangements the plate cannot be permanently attached to the shell, the shell shall be marked with

at least the information required by the pressure vessel code. As a minimum, at least the following

information shall be marked on the plate by stamping or by any other similar method:

(a) Owner information

(i) Owner’s registration number;

(b) Manufacturing information

(i) Country of manufacture;

(ii) Year of manufacture;

(iii) Manufacturer’s name or mark;

(iv) Manufacturer’s serial number;

(c) Approval information

(i) The United Nations packaging symbol

;

This symbol shall not be used for any purpose other than certifying that a packaging, a

flexible bulk container, a portable tank or a MEGC complies with the relevant

requirements in Chapter 6.1, 6.2, 6.3, 6.5, 6.6, 6.7 or 6.11;

(ii) Approval country;

(iii) Authorized body for the design approval;

(iv) Design approval number;

(v) Letters ‘AA’, if the design was approved under alternative arrangements (see 6.7.1.2);

(vi) Pressure vessel code to which the shell is designed;

(d) Pressures

(i) MAWP (in bar gauge or kPa gauge)3;

(ii) Test pressure (in bar gauge or kPa gauge)3;

(iii) Initial pressure test date (month and year);

3 The unit used shall be indicated.

(iv) Identification mark of the initial pressure test witness;

(v) External design pressure6 (in bar gauge or kPa gauge)3;

(e) Temperatures

(i) Design temperature range (in °C)3;

(ii) Design reference temperature (in °C)3;

(f) Materials

(i) Shell material(s) and material standard reference(s);

(ii) Equivalent thickness in reference steel (in mm)3;

(g) Capacity

(i) Tank water capacity at 20 °C (in litres)3;

(h) Periodic inspections and tests

(i) Type of the most recent periodic test (2.5-year, 5-year or exceptional);

(ii) Date of the most recent periodic test (month and year);

(iii) Test pressure (in bar gauge or kPa gauge)3 of the most recent periodic test (if applicable);

(iv) Identification mark of the authorized body who performed or witnessed the most recent

test.

6 See 6.7.3.2.8.

3 The unit used shall be indicated.

The following information shall be durably marked either on the portable tank itself or on a metal

plate firmly secured to the portable tank:

Name of the operator

Name of non-refrigerated liquefied gas(es) permitted for carriage

Maximum permissible load mass for each non-refrigerated liquefied gas permitted ________kg

Maximum permissible gross mass (MPGM)__________kg

Unladen (tare) mass_________kg

Portable tank instruction in accordance with 4.2.5.2.6

If a portable tank is designed and approved for handling in open seas, the words "OFFSHORE

PORTABLE TANK" shall be marked on the identification plate.

Requirements for the design, construction, inspection and testing of portable tanks intended for the carriage of refrigerated liquefied gases

Definitions

For the purposes of this section:

Alternative arrangement means an approval granted by the competent authority for a portable tank or

MEGC that has been designed, constructed or tested to technical requirements or testing methods

other than those specified in this Chapter;

Portable tank means a thermally insulated multimodal tank having a capacity of more than 450 litres

fitted with service equipment and structural equipment necessary for the carriage of refrigerated

liquefied gases. The portable tank shall be capable of being filled and discharged without the removal

of its structural equipment. It shall possess stabilizing members external to the tank, and shall be

capable of being lifted when full. It shall be designed primarily to be loaded onto a vehicle, wagon or

sea-going or inland navigation vessel and shall be equipped with skids, mountings or accessories to

facilitate mechanical handling. Tank-vehicles, tank-wagons, non-metallic tanks, intermediate bulk

containers (IBCs), gas cylinders and large receptacles are not considered to fall within the definition

for portable tanks;

Tank means a construction which normally consists of either :

(a) A jacket and one or more inner shells where the space between the shell(s) and the jacket is

exhausted of air (vacuum insulation) and may incorporate a thermal insulation system; or

(b) A jacket and an inner shell with an intermediate layer of solid thermally insulating material

(e.g. solid foam);

Shell means the part of the portable tank which retains the refrigerated liquefied gas intended for

carriage, including openings and their closures, but does not include service equipment or external

structural equipment;

Jacket means the outer insulation cover or cladding which may be part of the insulation system;

Service equipment means measuring instruments and filling, discharge, venting, safety, pressurizing,

cooling and thermal insulation devices;

Structural equipment means the reinforcing, fastening, protective and stabilizing members external to

the shell;

Maximum allowable working pressure (MAWP) means the maximum effective gauge pressure

permissible at the top of the shell of a loaded portable tank in its operating position including the

highest effective pressure during filling and discharge;

Test pressure means the maximum gauge pressure at the top of the shell during the pressure test;

Leakproofness test means a test using gas subjecting the shell and its service equipment, to an

effective internal pressure not less than 90% of the MAWP;

Maximum permissible gross mass (MPGM) means the sum of the tare mass of the portable tank and

the heaviest load authorized for carriage;

Holding time means the time that will elapse from the establishment of the initial filling condition

until the pressure has risen due to heat influx to the lowest set pressure of the pressure limiting

device(s);

Reference steel means a steel with a tensile strength of 370 N/mm2 and an elongation at fracture

of 27%;

Minimum design temperature means the temperature which is used for the design and construction of

the shell not higher than the lowest (coldest) temperature (service temperature) of the contents during

normal conditions of filling, discharge and carriage.

General design and construction requirements

Shells shall be designed and constructed in accordance with the requirements of a pressure vessel code

recognized by the competent authority. Shells and jackets shall be made of metallic materials suitable

for forming. Jackets shall be made of steel. Non-metallic materials may be used for the attachments

and supports between the shell and jacket, provided their material properties at the minimum design

temperature are proven to be sufficient. The materials shall in principle conform to national or

international material standards. For welded shells and jackets only materials whose weldability has

been fully demonstrated shall be used. Welds shall be skilfully made and afford complete safety.

When the manufacturing process or the materials make it necessary, the shell shall be suitably heat

treated to guarantee adequate toughness in the weld and in the heat affected zones. In choosing the

material, the minimum design temperature shall be taken into account with respect to risk of brittle

fracture, to hydrogen embrittlement, to stress corrosion cracking and to resistance to impact. When

fine grain steel is used, the guaranteed value of the yield strength shall be not more than 460 N/mm2

and the guaranteed value of the upper limit of the tensile strength shall be not more than 725 N/mm2

in accordance with the material specifications. Portable tank materials shall be suitable for the external

environment in which they may be carried.

Any part of a portable tank, including fittings, gaskets and pipe-work, which can be expected normally

to come into contact with the refrigerated liquefied gas carried shall be compatible with that

refrigerated liquefied gas.

Contact between dissimilar metals which could result in damage by galvanic action shall be avoided.

The thermal insulation system shall include a complete covering of the shell(s) with effective

insulating materials. External insulation shall be protected by a jacket so as to prevent the ingress of

moisture and other damage under normal carriage conditions.

When a jacket is so closed as to be gas-tight, a device shall be provided to prevent any dangerous

pressure from developing in the insulation space.

Portable tanks intended for the carriage of refrigerated liquefied gases having a boiling point below

minus (-) 182 °C at atmospheric pressure shall not include materials which may react with oxygen or

oxygen enriched atmospheres in a dangerous manner, when located in parts of the thermal insulation

when there is a risk of contact with oxygen or with oxygen enriched fluid.