TE12

Tanks shall be equipped with thermal insulation complying with the requirements of

6.8.3.2.14. If the SADT of the organic peroxide in the tank is 55 °C or less, or the tank is

constructed of aluminium, the shell shall be completely insulated. The sun shield and any part

of the tank not covered by it, or the outer sheathing of a complete lagging, shall be painted

white or finished in bright metal. The paint shall be cleaned before each transport journey and

renewed in case of yellowing or deterioration. The thermal insulation shall be free from

combustible matter. Tanks shall be fitted with temperature sensing devices.

Tanks shall be fitted with safety valves and emergency pressure-relief devices. Vacuum-relief

devices may also be used. Emergency pressure-relief devices shall operate at pressures

determined according to both the properties of the organic peroxide and the construction

characteristics of the tank. Fusible elements shall not be permitted in the body of the shell.

Tanks shall be fitted with spring-loaded safety valves to prevent significant pressure build-up

within the shell of the decomposition products and vapours released at a temperature of

50 °C. The capacity and start-to-discharge pressure of the safety-valve(s) shall be based on

the results of the tests specified in special provision TA2. The start-to-discharge pressure

shall however in no case be such that liquid could escape from the valve(s) if the tank were

overturned.

The emergency-relief devices may be of the spring-loaded or frangible types designed to vent

all the decomposition products and vapours evolved during a period of not less than one hour

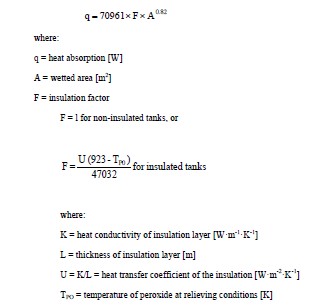

of complete fire-engulfment as calculated by the following formula:

The start-to-discharge pressure of the emergency-relief device(s) shall be higher than that

above specified and based on the results of the tests referred to in special provision TA2. The

emergency-relief devices shall be dimensioned in such a way that the maximum pressure in

the tank never exceeds the test pressure of the tank.

NOTE: An example of a method to determine the size of emergency-relief devices is given in

Appendix 5 of the Manual of Tests and Criteria.

and setting of the emergency-relief device(s) shall be determined assuming a loss of

insulation from 1% of the surface area.

Vacuum-relief devices and spring-loaded safety valves of tanks shall be provided with flame

arresters unless the substances to be carried and their decomposition products are noncombustible.

Due attention shall be paid to the reduction of the relief capacity caused by the

flame arrester.