USE OF PORTABLE TANKS AND UN MULTIPLE-ELEMENT GAS CONTAINERS (MEGCs)

NOTE 1: For fixed tanks (tank-vehicles), demountable tanks and tank-containers and tank swap bodies, with

shells made of metallic materials, and battery-vehicles and multiple element gas containers (MEGCs),

see Chapter 4.3; for fibre-reinforced plastics tanks, see Chapter 4.4; for vacuum operated waste

tanks, see Chapter 4.5.

NOTE 2: Portable tanks and UN MEGCs marked in accordance with the applicable provisions of Chapter 6.7

but which were approved in a State which is not a Contracting Party to ADR may nevertheless be

used for carriage under ADR.

General provisions for the use of portable tanks for the carriage of substances of Class 1 and Classes 3 to 9

This section provides general provisions applicable to the use of portable tanks for the carriage of

substances of Classes 1, 3, 4.1, 4.2, 4.3, 5.1, 5.2, 6.1, 6.2, 7, 8 and 9. In addition to these general

provisions, portable tanks shall conform to the design, construction, inspection and testing

requirements detailed in 6.7.2. Substances shall be carried in portable tanks conforming to the

applicable portable tank instruction identified in Column (10) of the Table A of Chapter 3.2 and

described in 4.2.5.2.6 (T1 to T23) and the portable tank special provisions assigned to each substance

in Column (11) of Table A of Chapter 3.2 and described in 4.2.5.3.

During carriage, portable tanks shall be adequately protected against damage to the shell and service

equipment resulting from lateral and longitudinal impact and overturning. If the shell and service

equipment are so constructed as to withstand impact or overturning it need not be protected in this

way. Examples of such protection are given in 6.7.2.17.5.

Certain substances are chemically unstable. They are accepted for carriage only when the necessary

steps have been taken to prevent their dangerous decomposition, transformation or polymerization

during carriage. To this end, care shall in particular be taken to ensure that shells do not contain any

substances liable to promote these reactions.

The temperature of the outer surface of the shell excluding openings and their closures or of the

thermal insulation shall not exceed 70 °C during carriage. When necessary, the shell shall be

thermally insulated.

Empty portable tanks not cleaned and not gas-free shall comply with the same provisions as portable

tanks filled with the previous substance.

Substances shall not be carried in the same or in adjoining compartments of shells when they may

react dangerously with each other (see definition for "dangerous reaction" in 1.2.1).

The design approval certificate, the test report and the certificate showing the results of the initial

inspection and test for each portable tank issued by the competent authority or its authorized body

shall be retained by the authority or body and the owner. Owners shall be able to provide this

documentation upon the request of any competent authority.

Unless the name of the substance(s) being carried appears on the metal plate described in 6.7.2.20.2 a

copy of the certificate specified in 6.7.2.18.1 shall be made available upon the request of a competent

authority or its authorized body and readily provided by the consignor, consignee or agent, as

appropriate.

Degree of filling

Prior to filling, the consignor shall ensure that the appropriate portable tank is used and that the

portable tank is not filled with substances which in contact with the materials of the shell, gaskets,

service equipment and any protective linings, are likely to react dangerously with them to form

dangerous products or appreciably weaken these materials. The consignor may need to consult the

manufacturer of the substance in conjunction with the competent authority for guidance on the

compatibility of the substance with the portable tank materials.

Portable tanks shall not be filled above the extent provided in 4.2.1.9.2 to 4.2.1.9.6. The applicability

of 4.2.1.9.2, 4.2.1.9.3 or 4.2.1.9.5.1 to individual substances is specified in the applicable portable

tank instruction or special provisions in 4.2.5.2.6 or 4.2.5.3 and Column (10) or (11) of Table A of

Chapter 3.2.

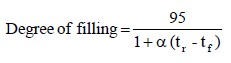

The maximum degree of filling (in %) for general use is determined by the formula:

| Degree of filling |

|

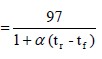

The maximum degree of filling (in %) for liquids of Class 6.1 and Class 8, in packing groups I and II,

and liquids with an absolute vapour pressure of more than 175 kPa (1.75 bar) at 65 °C, is determined

by the formula: