Packing and tank provisions

USE OF PACKAGINGS, INCLUDING INTERMEDIATE BULK CONTAINERS (IBCs) AND LARGE PACKAGINGS

General provisions for the packing of dangerous goods in packagings, including IBCs and large packagings

NOTE: For the packing of goods of Classes 2, 6.2 and 7, the general provisions of this section only

apply as indicated in 4.1.8.2 (Class 6.2), 4.1.9.1.5 (Class 7) and in the applicable packing instructions

of 4.1.4 (P201 and LP200 for Class 2 and P620, P621, IBC620 and LP621 for Class 6.2).

Dangerous goods shall be packed in good quality packagings, including IBCs and large packagings,

which shall be strong enough to withstand the shocks and loadings normally encountered during

carriage, including trans-shipment between cargo transport units and between cargo transport units

and warehouses as well as any removal from a pallet or overpack for subsequent manual or

mechanical handling. Packagings, including IBCs and large packagings, shall be constructed and

closed so as to prevent any loss of contents when prepared for transport which might be caused under

normal conditions of transport, by vibration, or by changes in temperature, humidity or pressure

(resulting from altitude, for example). Packagings, including IBCs and large packagings, shall be

closed in accordance with the information provided by the manufacturer. No dangerous residue shall

adhere to the outside of packagings, IBCs and large packagings during carriage. These provisions

apply, as appropriate, to new, reused, reconditioned or remanufactured packagings and to new, reused,

repaired or remanufactured IBCs, and to new, reused or remanufactured large packagings.

Parts of packagings, including IBCs and large packagings, which are in direct contact with dangerous

goods:

(a) shall not be affected or significantly weakened by those dangerous goods;

(b) shall not cause a dangerous effect e.g. catalysing a reaction or reacting with the dangerous

goods; and

(c) shall not allow permeation of the dangerous goods that could constitute a danger under normal

conditions of carriage.

Where necessary, they shall be provided with a suitable inner coating or treatment.

NOTE: For chemical compatibility of plastics packagings, including IBCs, made from polyethylene

see 4.1.1.21.

Unless otherwise provided elsewhere in ADR, each packaging, including IBCs and large packagings,

except inner packagings, shall conform to a design type successfully tested in accordance with the

requirements of 6.1.5, 6.3.5, 6.5.6 or 6.6.5, as applicable. The packagings for which the test is not

required are mentioned under 6.1.1.3.

When filling packagings, including IBCs and large packagings, with liquids, sufficient ullage (outage)

shall be left to ensure that neither leakage nor permanent distortion of the packaging occurs as a result

of an expansion of the liquid caused by temperatures likely to occur during transport. Unless specific

requirements are prescribed, liquids shall not completely fill a packaging at a temperature of 55 °C.

However, sufficient ullage shall be left in an IBC to ensure that at the mean bulk temperature of 50 °C

it is not filled to more than 98% of its water capacity. For a filling temperature of 15 °C, the

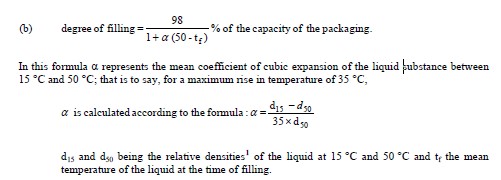

maximum degree of filling shall be determined as follows, unless otherwise provided, either:

(a)

|

Boiling point (initial boiling point) of

the substance in °C

|

< 60 |

≥ 60 < 100 |

≥ 100 < 200 |

≥ 200 < 300 |

≥ 300 |

|

Degree of filling as a percentage of the

capacity of the packaging

|

90 |

92 |

94 |

96 |

98 |

or

Inner packagings shall be packed in an outer packaging in such a way that, under normal conditions of

carriage, they cannot break, be punctured or leak their contents into the outer packaging. Inner

packagings containing liquids shall be packed with their closures upward and placed within outer

packagings consistent with the orientation marks prescribed in 5.2.1.10. Inner packagings that are

liable to break or be punctured easily, such as those made of glass, porcelain or stoneware or of

certain plastics materials, etc., shall be secured in outer packagings with suitable cushioning material.

Any leakage of the contents shall not substantially impair the protective properties of the cushioning

material or of the outer packaging.

Where an outer packaging of a combination packaging or a large packaging has been successfully

tested with different types of inner packagings, a variety of such different inner packagings may also

be assembled in this outer packaging or large packaging. In addition, provided an equivalent level of

performance is maintained, the following variations in inner packagings are allowed without further

testing of the package:

(a) Inner packagings of equivalent or smaller size may be used provided:

(i) the inner packagings are of similar design to the tested inner packagings

(e.g. shape - round, rectangular, etc.);

(ii) the material of construction of the inner packagings (glass, plastics, metal, etc.) offers

resistance to impact and stacking forces equal to or greater than that of the originally

tested inner packaging;

(iii) the inner packagings have the same or smaller openings and the closure is of similar

design (e.g. screw cap, friction lid, etc.);

(iv) sufficient additional cushioning material is used to take up void spaces and to prevent

significant movement of the inner packagings; and

(v) inner packagings are oriented within the outer packaging in the same manner as in the

tested package.

(b) A lesser number of the tested inner packagings, or of the alternative types of inner packagings

identified in (a) above, may be used provided sufficient cushioning is added to fill the void

space(s) and to prevent significant movement of the inner packagings.

Use of supplementary packagings within an outer packaging (e.g. an intermediate packaging or a

receptacle inside a required inner packaging) additional to what is required by the packing instructions

is authorized provided all relevant requirements are met, including those of 4.1.1.3, and, if

appropriate, suitable cushioning is used to prevent movement within the packaging.

Dangerous goods shall not be packed together in the same outer packaging or in large packagings,

with dangerous or other goods if they react dangerously with each other and cause:

(a) combustion or evolution of considerable heat;

1 Relative density (d) is considered to be synonymous with specific gravity (SG) and will be used throughout this

Chapter.

(b) evolution of flammable, asphyxiant, oxidizing or toxic gases;

(c) the formation of corrosive substances; or

(d) the formation of unstable substances.

NOTE: For mixed packing special provisions, see 4.1.10.

The closures of packagings containing wetted or diluted substances shall be such that the percentage

of liquid (water, solvent or phlegmatizer) does not fall below the prescribed limits during transport.

Where two or more closure systems are fitted in series on an IBC, that nearest to the substance being

carried shall be closed first.

Where pressure may develop in a package by the emission of gas from the contents (as a result of

temperature increase or other causes), the packaging or IBC may be fitted with a vent provided that

the gas emitted will not cause danger on account of its toxicity, its flammability or the quantity

released, for example.

A venting device shall be fitted if dangerous overpressure may develop due to normal decomposition

of substances. The vent shall be so designed that, when the packaging or IBC is in the attitude in

which it is intended to be carried, leakages of liquid and the penetration of foreign substances are

prevented under normal conditions of carriage.

NOTE: Venting of the package is not permitted for air carriage.

Liquids may only be filled into inner packagings which have an appropriate resistance to internal

pressure that may be developed under normal conditions of carriage.