Where dry ice is placed around packages, measures shall be taken to ensure that packages remain in

the original position during carriage after the dry ice has dissipated.

Marking of vehicles and containers

Vehicles and containers containing dangerous goods used for cooling or conditioning purposes that

are not well ventilated shall be marked with a warning mark, as specified in 5.5.3.6.2, affixed at each

access point in a location where it will be easily seen by persons opening or entering the vehicle or

container. This mark shall remain on the vehicle or container until the following provisions are met:

(a) The vehicle or container has been well ventilated to remove harmful concentrations of coolant

or conditioner; and

(b) The cooled or conditioned goods have been unloaded.

As long as the vehicle or container is marked, the necessary precautions have to be taken before

entering it. The necessity of ventilating through the cargo doors or other means (e.g. forced

ventilation) has to be evaluated and included in training of the involved persons.

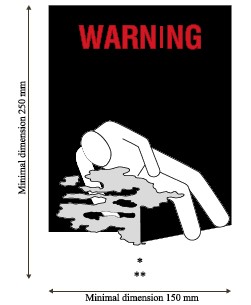

The warning mark shall be as shown in Figure 5.5.3.6.2.

Figure 5.5.3.6.2

Coolant/conditioning warning mark for vehicles and containers

Insert the name indicated in Column (2) of Table A of Chapter 3.2 of the

coolant/conditioner. The lettering shall be in capitals, all be on one line and shall be at least 25 mm

high. If the length of the proper shipping name is too long to fit in the space provided, the lettering

may be reduced to the maximum size possible to fit. For example: "CARBON DIOXIDE, SOLID".

Insert "AS COOLANT" or "AS CONDITIONER" as appropriate. The lettering shall be in

capitals, all be on one line and be at least 25 mm high.

The mark shall be a rectangle. The minimum dimensions shall be 150 mm wide x 250 mm high. The

word "WARNING" shall be in red or white and be at least 25 mm high. Where dimensions are not

specified, all features shall be in approximate proportion to those shown.

The word "WARNING" and the words "AS COOLANT" or "AS CONDITIONER", as appropriate,

shall be in an official language of the country of origin and also, if that language is not English,

French or German, in English, French or German, unless agreements concluded between the countries

concerned in the transport operation provide otherwise.

Documentation

Documents (such as a bill of lading, cargo manifest or CMR/CIM consignment note) associated with

the carriage of vehicles or containers containing or having contained substances used for cooling

or conditioning purposes and have not been completely ventilated before carriage shall include the

following information:

(a) The UN number preceded by the letters "UN"; and

(b) The name indicated in Column (2) of Table A of Chapter 3.2 followed by the words "AS COOLANT"

or "AS CONDITIONER" as appropriate in an official language of the country of origin and also, if

that language is not English, French or German, in English, French or German, unless agreements, if

any, concluded between the countries concerned in the transport operation provide otherwise.

For example: UN 1845, CARBON DIOXIDE, SOLID, AS COOLANT.

The transport document may be in any form, provided it contains the information required in

5.5.3.7.1. This information shall be easy to identify, legible and durable.

Requirements for the construction and testing of packagings, intermediate bulk containers (IBCs), large packagings, tanks and bulk containers

REQUIREMENTS FOR THE CONSTRUCTION AND TESTING OF PACKAGINGS

General

The requirements of this Chapter do not apply to:

(a) Packages containing radioactive material of Class 7, unless otherwise provided (see 4.1.9);

(b) Packages containing infectious substances of Class 6.2, unless otherwise provided

(see Chapter 6.3, Note and packing instruction P621 of 4.1.4.1);

(c) Pressure receptacles containing gases of Class 2;

(d) Packages whose net mass exceeds 400 kg;

(e) Packagings for liquids, other than combination packagings, with a capacity exceeding

450 litres.

The requirements for packagings in 6.1.4 are based on packagings currently used. In order to take into

account progress in science and technology, there is no objection to the use of packagings having

specifications different from those in 6.1.4, provided that they are equally effective, acceptable to the

competent authority and able successfully to withstand the tests described in 6.1.1.3 and 6.1.5.

Methods of testing other than those described in this Chapter are acceptable, provided they are

equivalent, and are recognized by the competent authority.

Every packaging intended to contain liquids shall successfully undergo a suitable leakproofness test.

This test is part of a quality assurance programme as stipulated in 6.1.1.4 which shows the capability

of meeting the appropriate test level indicated in 6.1.5.4.3:

(a) Before it is first used for carriage;

(b) After remanufacturing or reconditioning, before it is re-used for carriage;

For this test, packagings need not have their own closures fitted.

The inner receptacle of composite packagings may be tested without the outer packaging provided the

test results are not affected.

This test is not necessary for:

- Inner packagings of combination packagings;

- Inner receptacles of composite packagings (glass, porcelain or stoneware), marked with the

symbol "RID/ADR" according to 6.1.3.1 (a) (ii);

- Light gauge metal packagings, marked with the symbol "RID/ADR" according to

6.1.3.1 (a) (ii).

Packagings shall be manufactured, reconditioned and tested under a quality assurance programme

which satisfies the competent authority in order to ensure that each packaging meets the requirements

of this Chapter.

NOTE: ISO 16106:2006 "Packaging – Transport packages for dangerous goods – Dangerous

goods packagings, intermediate bulk containers (IBCs) and large packagings – Guidelines for the

application of ISO 9001" provides acceptable guidance on procedures which may be followed.

Manufacturers and subsequent distributors of packagings shall provide information regarding

procedures to be followed and a description of the types and dimensions of closures (including

required gaskets) and any other components needed to ensure that packages as presented for carriage

are capable of passing the applicable performance tests of this Chapter.