portable tank special provisions

portable tank special provisions are assigned to certain substances to indicate provisions which are in

addition to or in lieu of those provided by the portable tank instructions or the requirements in

chapter 6.7. portable tank special provisions are identified by an alpha numeric code beginning with

the letters "tp" (tank provision) and are assigned to specific substances in column (11) of table a of

chapter 3.2. the following is a list of the portable tank special provisions:

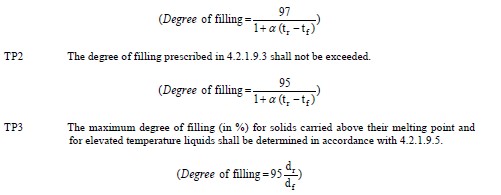

tp1 the degree of filling prescribed in 4.2.1.9.2 shall not be exceeded.

tp4 the degree of filling shall not exceed 90% or, alternatively, any other value approved by

the competent authority (see 4.2.1.16.2).

tp5 the degree of filling prescribed in 4.2.3.6 shall be met.

tp6 to prevent the tank bursting in any event, including fire engulfment, it shall be provided

with pressure-relief devices which are adequate in relation to the capacity of the tank

and to the nature of the substance carried. the device shall also be compatible with the

substance.

tp7 air shall be eliminated from the vapour space by nitrogen or other means.

tp8 the test pressure may be reduced to 1.5 bar when the flash point of the substances

carried is greater than 0 °c.

tp9 a substance under this description shall only be carried in a portable tank under an

approval granted by the competent authority.

tp10 a lead lining, not less than 5 mm thick, which shall be tested annually, or another

suitable lining material approved by the competent authority is required.

tp12 (deleted)

tp13 (reserved)

tp16 the tank shall be fitted with a special device to prevent under-pressure and excess

pressure during normal carriage conditions. this device shall be approved by the

competent authority.

pressure-relief requirements are as indicated in 6.7.2.8.3 to prevent crystallization of the

product in the pressure-relief valve.

tp17 only inorganic non-combustible materials shall be used for thermal insulation of the

tank.

tp18 temperature shall be maintained between 18 °c and 40 °c. portable tanks containing

solidified methacrylic acid shall not be reheated during carriage.

tp19 the calculated shell thickness shall be increased by 3 mm. shell thickness shall be

verified ultrasonically at intervals midway between periodic hydraulic tests.

tp20 this substance shall only be carried in insulated tanks under a nitrogen blanket.

tp21 the shell thickness shall be not less than 8 mm. tanks shall be hydraulically tested and

internally inspected at intervals not exceeding 2.5 years.

tp22 lubricant for joints or other devices shall be oxygen compatible.

tp23 deleted.

tp24 the portable tank may be fitted with a device located under maximum filling conditions

in the vapour space of the shell to prevent the build up of excess pressure due to the

slow decomposition of the substance carried. this device shall also prevent an

unacceptable amount of leakage of liquid in the case of overturning or entry of foreign

matter into the tank. this device shall be approved by the competent authority or its

authorized body.

tp25 sulphur trioxide 99.95% pure and above may be carried in tanks without an inhibitor

provided that it is maintained at a temperature equal to or above 32.5 °c.

tp26 when carried under heated conditions, the heating device shall be fitted outside the

shell. for un 3176 this requirement only applies when the substance reacts dangerously

with water.

tp27 a portable tank having a minimum test pressure of 4 bar may be used if it is shown that

a test pressure of 4 bar or less is acceptable according to the test pressure definition

in 6.7.2.1.

tp28 a portable tank having a minimum test pressure of 2.65 bar may be used if it is shown

that a test pressure of 2.65 bar or less is acceptable according to the test pressure

definition in 6.7.2.1.

tp29 a portable tank having a minimum test pressure of 1.5 bar may be used if it is shown

that a test pressure of 1.5 bar or less is acceptable according to the test pressure

definition in 6.7.2.1.

tp30 this substance shall be carried in insulated tanks.

tp31 this substance may only be carried in tanks in the solid state.

tp32 for un nos. 0331, 0332 and 3375, portable tanks may be used subject to the following

conditions:

(a) to avoid unnecessary confinement, each portable tank constructed of metal shall

be fitted with a pressure-relief device that may be of the reclosing spring-loaded

type, a frangible disc or a fusible element. the set to discharge or burst pressure,

as applicable, shall not be greater than 2.65 bar for portable tanks with minimum

test pressures greater than 4 bar.

(b) for un 3375 only, the suitability for carriage in tanks shall be demonstrated. one

method to evaluate this suitability is test 8 (d) in test series 8 (see manual of

tests and criteria, part 1, sub-section 18.7).

(c) substances shall not be allowed to remain in the portable tank for any period that

could result in caking. appropriate measures shall be taken to avoid accumulation

and packing of substances in the tank (e.g. cleaning, etc).

tp33 the portable tank instruction assigned for this substance applies to granular and

powdered solids and to solids which are filled and discharged at temperatures above

their melting point which are cooled and carried as a solid mass. for solids which are

carried above their melting point, see 4.2.1.19.

tp34 portable tanks need not be subjected to the impact test in 6.7.4.14.1 if the portable tank

is marked "not for rail transport" on the plate specified in 6.7.4.15.1 and

also in letters of at least 10 cm high on both sides of the outer jacket.

tp35 deleted.

tp36 fusible elements in the vapour space may be used on portable tanks.

tp37 deleted.

tp38 portable tank instruction t9 prescribed in adr applicable up to 31 december 2012 may

continue to be applied until 31 december 2018.

tp39 portable tank instruction t4 prescribed in adr applicable up to 31 december 2012 may

continue to be applied until 31 december 2018.

tp40 portable tanks shall not be carried when connected with spray application equipment.

tp41 with the agreement of the competent authority, the 2.5 year internal examination may be

waived or substituted by other test methods or inspection procedures, provided that the

portable tank is dedicated to the carriage of the organometallic substances to which this

tank special provision is assigned. however this examination is required when the

conditions of 6.7.2.19.7 are met.