Portable tanks meeting the definition of container in the International Convention for Safe Containers

(CSC), 1972, as amended, shall not be used unless they are successfully qualified by subjecting a

representative prototype of each design to the Dynamic, Longitudinal Impact Test prescribed in the

Manual of Tests and Criteria, Part IV, Section 41.

The shell and items of equipment of each portable tank shall be inspected and tested before being put

into service for the first time (initial inspection and test) and thereafter at not more than five-year

intervals (5 year periodic inspection and test) with an intermediate periodic inspection and test (2.5

year periodic inspection and test) midway between the 5 year periodic inspections and tests. The 2.5

year inspection and test may be performed within 3 months of the specified date. An exceptional

inspection and test shall be performed regardless of the last periodic inspection and test when

necessary according to 6.7.3.15.7.

The initial inspection and test of a portable tank shall include a check of the design characteristics, an

internal and external examination of the portable tank and its fittings with due regard to the nonrefrigerated

liquefied gases to be carried, and a pressure test referring to the test pressures according to

6.7.3.3.2. The pressure test may be performed as a hydraulic test or by using another liquid or gas with

the agreement of the competent authority or its authorized body. Before the portable tank is placed

into service, a leakproofness test and a test of the satisfactory operation of all service equipment shall

also be performed. When the shell and its fittings have been pressure-tested separately, they shall be

subjected together after assembly to a leakproofness test. All welds subject to full stress level in the

shell shall be inspected during the initial test by radiographic, ultrasonic, or another suitable nondestructive

test method. This does not apply to the jacket.

2 Distinguishing sign of the State of registration used on motor vehicles and trailers in international road traffic,

e.g. in accordance with the Geneva Convention on Road Traffic of 1949 or the Vienna Convention on Road Traffic of

1968.

The 5 year periodic inspection and test shall include an internal and external examination and, as a

general rule, a hydraulic pressure test. Sheathing, thermal insulation and the like shall be removed

only to the extent required for reliable appraisal of the condition of the portable tank. When the shell

and equipment have been pressure-tested separately, they shall be subjected together after assembly to

a leakproofness test.

The intermediate 2.5 year periodic inspection and test shall at least include an internal and external

examination of the portable tank and its fittings with due regard to the non-refrigerated liquefied gases

intended to be carried, a leakproofness test and a check of the satisfactory operation of all service

equipment. Sheathing thermal insulation and the like shall be removed only to the extent required for

reliable appraisal of the condition of the portable tank. For portable tanks intended for the carriage of a

single non-refrigerated liquefied gas, the 2.5 year internal examination may be waived or substituted

by other test methods or inspection procedures specified by the competent authority or its authorized

body.

A portable tank may not be filled and offered for carriage after the date of expiry of the last 5 year or

2.5 year periodic inspection and test as required by 6.7.3.15.2. However a portable tank filled prior to

the date of expiry of the last periodic inspection and test may be carried for a period not to exceed

three months beyond the date of expiry of the last periodic test or inspection. In addition, a portable

tank may be carried after the date of expiry of the last periodic test and inspection:

(a) After emptying but before cleaning, for purposes of performing the next required test or

inspection prior to refilling; and

(b) Unless otherwise approved by the competent authority, for a period not to exceed six months

beyond the date of expiry of the last periodic test or inspection, in order to allow the return of

dangerous goods for proper disposal or recycling. Reference to this exemption shall be

mentioned in the transport document.

The exceptional inspection and test is necessary when the portable tank shows evidence of damaged

or corroded areas, or leakage, or other conditions that indicate a deficiency that could affect the

integrity of the portable tank. The extent of the exceptional inspection and test shall depend on the

amount of damage or deterioration of the portable tank. It shall include at least the 2.5 year inspection

and test according to 6.7.3.15.5.

The internal and external examinations shall ensure that:

(a) The shell is inspected for pitting, corrosion, or abrasions, dents, distortions, defects in welds or

any other conditions, including leakage, that might render the portable tank unsafe for carriage.

The wall thickness shall be verified by appropriate measurement if this inspection indicates a

reduction of wall thickness;

(b) The piping, valves, and gaskets are inspected for corroded areas, defects, or any other

conditions, including leakage, that might render the portable tank unsafe for filling, discharge

or carriage;

(c) Devices for tightening manhole covers are operative and there is no leakage at manhole covers

or gaskets;

(d) Missing or loose bolts or nuts on any flanged connection or blank flange are replaced or

tightened;

(e) All emergency devices and valves are free from corrosion, distortion and any damage or defect

that could prevent their normal operation. Remote closure devices and self-closing stop-valves

shall be operated to demonstrate proper operation;

(f) Required marks on the portable tank are legible and in accordance with the applicable

requirements; and

(g) The framework, the supports and the arrangements for lifting the portable tank are in

satisfactory condition.

The inspections and tests in 6.7.3.15.1, 6.7.3.15.3, 6.7.3.15.4, 6.7.3.15.5 and 6.7.3.15.7 shall be

performed or witnessed by an expert approved by the competent authority or its authorized body.

When the pressure test is a part of the inspection and test, the test pressure shall be the one indicated

on the data plate of the portable tank. While under pressure, the portable tank shall be inspected for

any leaks in the shell, piping or equipment.

In all cases when cutting, burning or welding operations on the shell have been effected, that work

shall be to the approval of the competent authority or its authorized body taking into account the

pressure vessel code used for the construction of the shell. A pressure test to the original test pressure

shall be performed after the work is completed.

When evidence of any unsafe condition is discovered, the portable tank shall not be returned to

service until it has been corrected and the pressure test is repeated and passed.

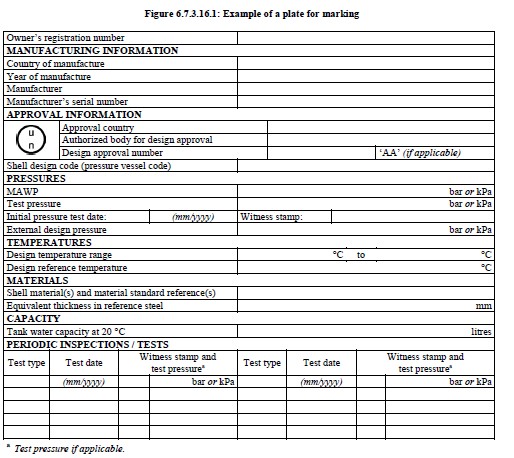

Marking

Every portable tank shall be fitted with a corrosion resistant metal plate permanently attached to the

portable tank in a conspicuous place readily accessible for inspection. When for reasons of portable

tank arrangements the plate cannot be permanently attached to the shell, the shell shall be marked with

at least the information required by the pressure vessel code. As a minimum, at least the following

information shall be marked on the plate by stamping or by any other similar method:

(a) Owner information

(i) Owner’s registration number;

(b) Manufacturing information

(i) Country of manufacture;

(ii) Year of manufacture;

(iii) Manufacturer’s name or mark;

(iv) Manufacturer’s serial number;

(c) Approval information

(i) The United Nations packaging symbol

;

This symbol shall not be used for any purpose other than certifying that a packaging, a

flexible bulk container, a portable tank or a MEGC complies with the relevant

requirements in Chapter 6.1, 6.2, 6.3, 6.5, 6.6, 6.7 or 6.11;

(ii) Approval country;

(iii) Authorized body for the design approval;

(iv) Design approval number;

(v) Letters ‘AA’, if the design was approved under alternative arrangements (see 6.7.1.2);

(vi) Pressure vessel code to which the shell is designed;

(d) Pressures

(i) MAWP (in bar gauge or kPa gauge)3;

(ii) Test pressure (in bar gauge or kPa gauge)3;

(iii) Initial pressure test date (month and year);

3 The unit used shall be indicated.

(iv) Identification mark of the initial pressure test witness;

(v) External design pressure6 (in bar gauge or kPa gauge)3;

(e) Temperatures

(i) Design temperature range (in °C)3;

(ii) Design reference temperature (in °C)3;

(f) Materials

(i) Shell material(s) and material standard reference(s);

(ii) Equivalent thickness in reference steel (in mm)3;

(g) Capacity

(i) Tank water capacity at 20 °C (in litres)3;

(h) Periodic inspections and tests

(i) Type of the most recent periodic test (2.5-year, 5-year or exceptional);

(ii) Date of the most recent periodic test (month and year);

(iii) Test pressure (in bar gauge or kPa gauge)3 of the most recent periodic test (if applicable);

(iv) Identification mark of the authorized body who performed or witnessed the most recent

test.

6 See 6.7.3.2.8.

3 The unit used shall be indicated.

The following information shall be durably marked either on the portable tank itself or on a metal

plate firmly secured to the portable tank:

Name of the operator

Name of non-refrigerated liquefied gas(es) permitted for carriage

Maximum permissible load mass for each non-refrigerated liquefied gas permitted ________kg

Maximum permissible gross mass (MPGM)__________kg

Unladen (tare) mass_________kg

Portable tank instruction in accordance with 4.2.5.2.6

If a portable tank is designed and approved for handling in open seas, the words "OFFSHORE

PORTABLE TANK" shall be marked on the identification plate.